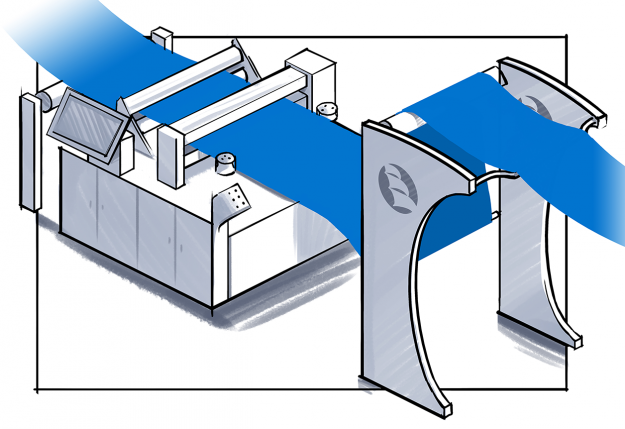

Stenter Applications – Technical Textiles / Nonwoven

High Speed & High Pull Capabilities Optimal Drying & Heating Rates Lowest Energy consumption for kg Processed Heat Recovery Systems Available Multiple Inlet / Outlet Configurations to match process Wide…