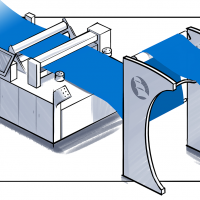

Pak Nit II e3+ Compactor

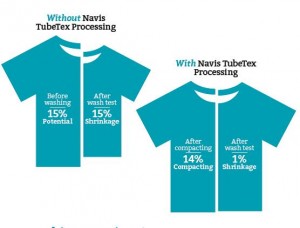

Achieve a new level of performance and appearance for tubular knit fabrics with the Navis TubeTex Pak Nit II e3+ Compactor. For high quality outerwear and apparel knit fabrics, your facility’s final step of processing will yield a softer hand as well as superior shrinkage, width and yield control.

THE PAK NIT II E3+ OFFERS SEVERAL DISTINCT ADVANTAGES:

- Improved hand and appearance all while achieving the natural relaxed state of the knit loop in a continuous process

- Residual shrinkage results of only 1% in knit fabric by tumble dry testing

- High Processing speeds, over 40 min per minute

- Patented processing system means accurate repeatability of desired finishing results

Shoe Quadrant Adjustment

The shoe quadrant adjustment allows the operator to make quick and precise changes in fabric styles without changing machine settings and provides a quick-cleaning feature.

The numbered quadrants give exact setting standards for each type of fabric processed.

It also allows for minimum and maximum settings for shoe tips for the compaction station to prevent mis-adjustment.

Hot Oil Heating System

Our heating system was redesigned to improve the uniformity of heat, which greatly reduces downtime, maintenance and power usage required by the Pak Nit II e3+. The closed-loop oil heating setup is environmentally safe and makes use of the plant’s steam.

Fabric Width Control

The Pak Nit II e3+ uses an internal belt-driven expander to spread fabric to the desired finished width. Our patented Touch-O-Matic low pressure gas-charged expander allows width adjustments while the machine is in operation.

The complete system is designed to avoid any marking on the fabric tube.

COMPACTING PRINCIPLE

The compaction section uses two rolls and two heated shoes to present the fabric into the compaction zone. A feed roll overfeeds fabric, while the slower retard roll holds the fabric in the compaction zone. By decreasing the retard roll speed, the machine operator can reduce length shrinkage and increase compaction up to 25%.

Operator Interface

The large Touchscreen operator panel controls multiple machine functions to ensure quick and easy operation.

The Multi-language support and remote troubleshooting are standard to simplify training and increase production time. Maintenance Manager, Shift Manager, Technical data, drawings and information on-board the screen.

Machine Specifications

- Speed 0-90 yards/min (~82 m/m)

- Width:

40″ (17-94 cm)

50″ (17-119 cm)

60″ (17-145 cm)