C-2500 MC+ Open Width Compactor

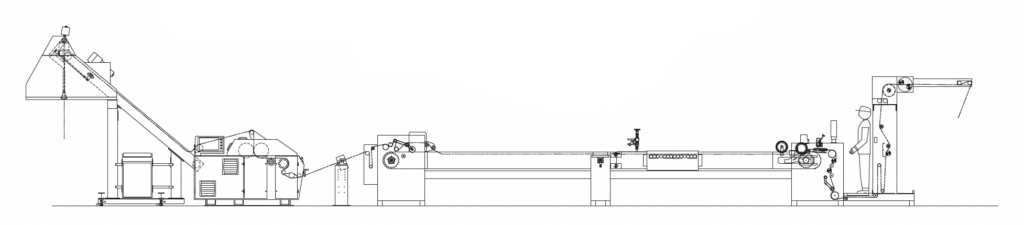

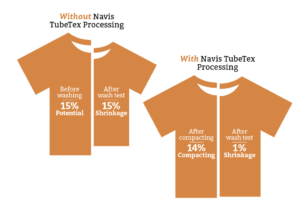

Building on the success and history of the previous model compactors, the Navis TubeTex C-2500 MC+ is continuing to make history. The Navis TubeTex C-2500 MC+ provides total control of shrinkage, yield and width. The Navis C-2500 MC+ can produce residual length shrinkage values down to 3% and below by tumble dry testing on Cotton, Viscose, Lycra, and many other high fashion blends. The C-2500 MC+ incorporates many engineering breakthroughs that translate to faster change over for fabric styles and higher quality finishing while reducing running cost.

The machine will produce high quality outerwear and apparel knit fabrics with a softer hand, superior shrinkage control, width control, and yield control. An optional Automatic Width Control and Automatic Stitch Control devices are available for further ease of operation.

-

Compaction Rates up to 25%

-

Next Generation Advanced Roll Technologies

-

Sensitive Fabric Entry System

-

Enhanced Edge Decurling Ability

-

Comprehensive Steaming System

-

New Generation Oil Heating System

-

Reduced Carbon Footprint by 20%

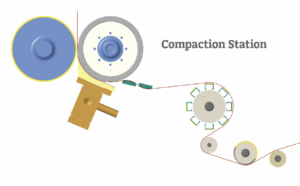

Fabric Width Control – Bilateral Spreader

Fabric width is controlled just prior to entering the compaction zone by the Bilateral Spreader. The Bilateral Spreader maintains fabric width by opening and closing via input by an operator selectable width sensors.

New Generation Oil Heating System

The Recirculating Oil heating system uses plant steam to heat a closed loop to heat the shoe and feed roll. Separate control loops for the feed roll and shoe ensure that each loop maintains uniform temperature. The closed-loop oil heating system setup is environmentally safe and efficient.

Pin Tenter Entry (Option)

When the process requires, Navis TubeTex can add aPin Tenter Entry.

• 9 meter (30 feet) Pin Tenter Entry