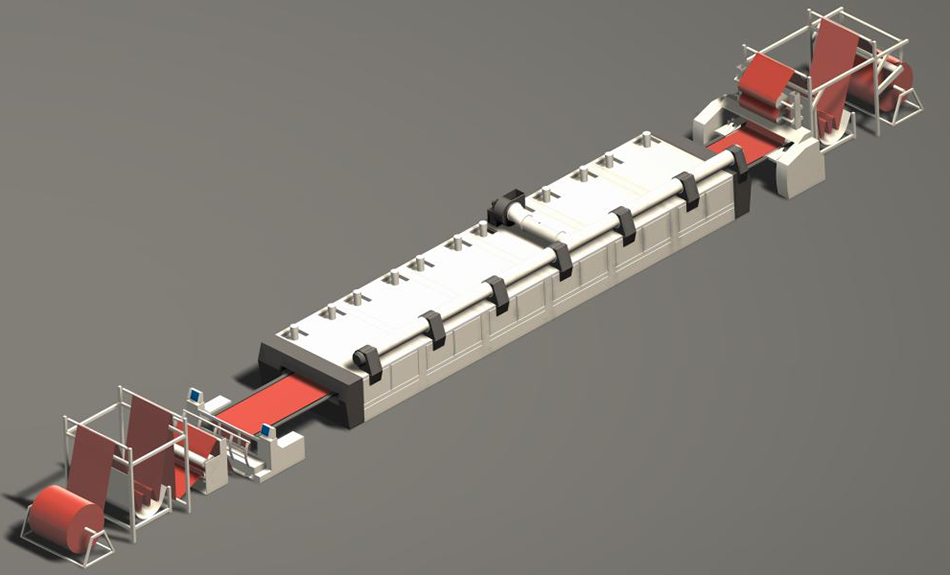

Woven Fabrics

- High Speed & High Pull Capabilities

- Versatile for many types of fabrics

- Clip. Pin or Combination Chain Styles Available

- Speeds to 200 m/m – Optimal Drying & Heating Rates

- Low Energy consumption for kg Processed

- Heat Recovery Systems Available

- Multiple Inlet / Outlet Configurations to match process

- Wide Range of Chemical Application technologies (Coating, Saturation, Foam)

- Powerful / Precise yet Intuitive Control Platform

- Remote Access / Control – Standard Widths up to 3.8 m

- Turnkey Solutions

- Industry 4.0 ready

M&W began building stenters for the textile & plastic markets in 1920. When non-woven and technical webs entered the markets, M&W became the leader in servicing these applications requiring specialized stenters.