Ultra-Nit Dryer

The Ultra-Nit Dryer is a true three active pass dryer and carries the fabric without tension between two belts on each pass through the dryer. Each pass is active, meaning that the fabric is exposed to a consistent airflow across the full width during every pass.

The Ultra-Nit provides for a tremendous amount of flexibility with respect to it’s overfeed capabilities. Overfeed from the entry to the first pass can be adjusted while the machine is in operation. Additional overfeed can be set up between each pass to so that both shrinkage and drying efficiency can be maximized.

Depending on configuration, the Ultra-Nit Dryer attains production levels of 10 to 50 tons per day.

Special Features

- Standard belt width 132″ (3,400 mm), 126″ (3,200 mm) working width

- Heating options: Steam Heat Exchanger, Thermal Oil Heat Exchanger or Gas Burner

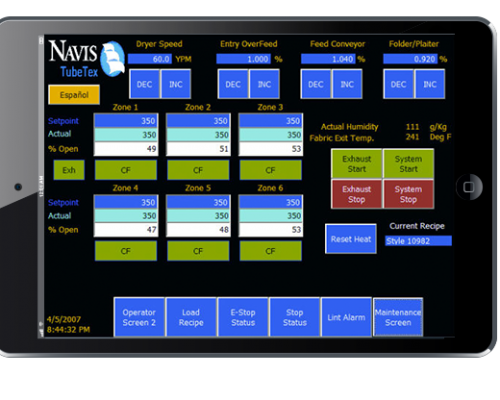

- Touchscreen interface with alarm reporting

- More uniform airflow to maximize full width of dryer and production capacity

- AC inverter circulation fans – allows reduction of air flow and electricity for lighter fabrics and reduced energy consumption

Available Options

- Automatic continuous lint belt cleaning system – maintains maximum drying efficiency and reduces downtime

- Exhaust Air Humidity Control – maintains constant exhaust air saturation, reducing energy used per unit produced

- Exit Fabric Temperature and Moisture Control

- Infrared temperature and moisture control monitors the fabric at the exit to ensure maximum dryer output

Master-Nit Dryer

Master-Nit Dryer

The Master-Nit Relax Conveyor Dryer for tubular and open-width fabrics is the right size for the right job. The Master-Nit Dryer is a true 3 active pass dryer and carries the fabric without tension between two belts on each pass through the dryer. Each pass is active, meaning that the fabric is exposed to a consistent airflow across the full width during every pass.

The Master-Nit provides a tremendous amount of flexibility with respect to it’s overfeed capabilities. Overfeed from the entry to the first pass can be adjusted while the machine is in operation. Additional overfeed can be set up between each pass to so that both shrinkage and drying efficiency can be maximized. Depending on configuration, the Master-Nit Dryer attains production levels of 3 to 20 tons per day.

Specifications:

- Standard belt width 102″ (2,600 mm), working width 98″ (2,500 mm)

- Heating options: Steam Heat Exchanger, Thermal Oil Heat Exchanger or Gas Burner

- More uniform airflow to maximize full width of dryer and production capacity

- Manual lint belt cleaning system

- AC inverter circulation fans – allows reduction of air flow and electricity for lighter fabrics and reduced energy consumption.

The Ultra-Nit Advanced Nozzle arrangement permits the fabric to bulk and the knitted loop to relax, producing finished fabrics with better hand, more weight and increased stitches.

All Navis TubeTex dryers have advanced nozzle, airflow and thermal properties designed to optimize residual shrinkage values, eliminating the need for high-energy-cost shaking or steaming attachments.