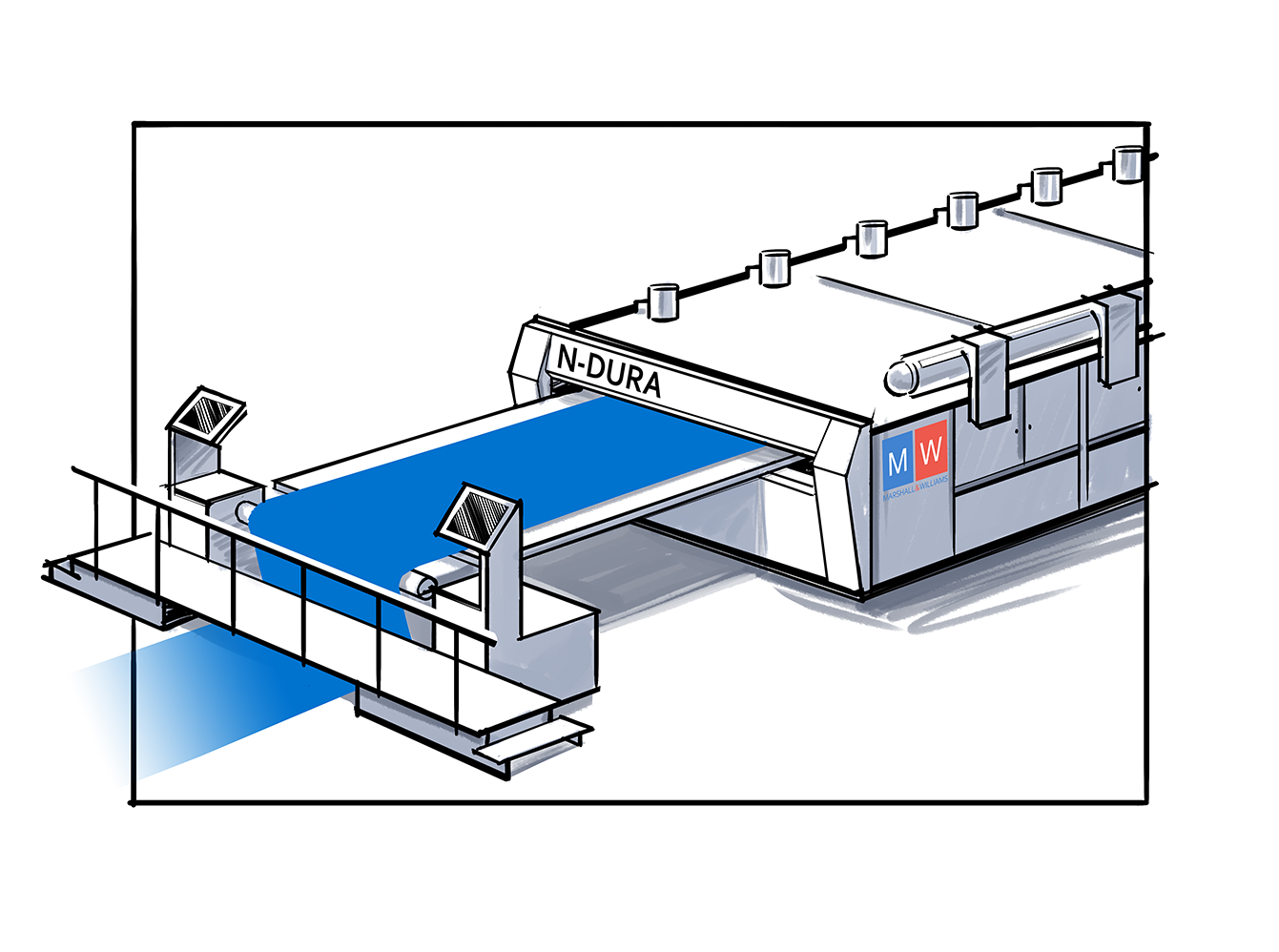

The N-Dura Dryer was developed by engineers using the latest thermal & aerodynamic modeling techniques to optimize air flow patterns and heat distribution; concurrently, industrial designers developed a structure that was easy to install, operate and maintain.

Performance Features:

- Unique Nozzle design using CFD Analysis optimizes velocity and uniformity while minimizing power requirements.

- Housing losses 43% less than conventional designs. Heat radiation to room is minimized.

- All wired & piped components (fans, burners, motors, coils) are located on same side of dryer minimizing floor space, providing easy access for cleaning, and facilitating easy installation and troubleshooting.

- Heat Recovery (internal and stand alone) systems available. Savings are process dependent.

Filter Cleaning & Access

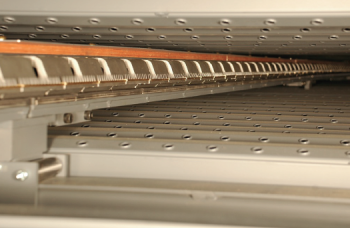

- Individually removable nozzles with clean-out doors.

- Large Return air filters cleaned while in operation. Frequency is process dependent.

- Duplex filters ensure process air is filtered during cleaning.

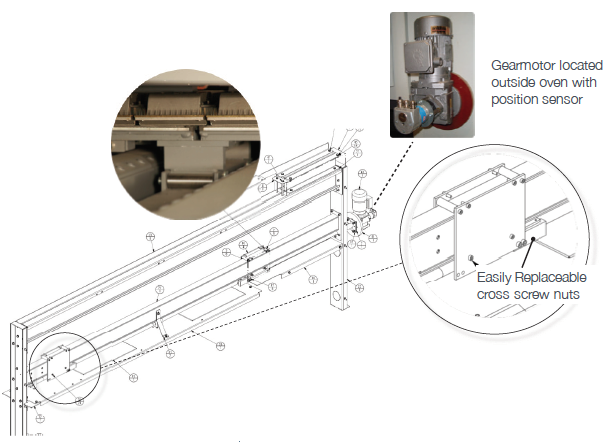

Width Adjustment System

- Direct coupled gear motors outside of dryer eliminate maintenance problems with chains and sprockets. Rails positioned to preset width (recipe or operator selectable).

- Position Sensor displays rail location at each joint and eliminates damage caused by extreme rail angles.

- Precision saddles support rails from tipping caused by pull forces and web close to nozzles for efficient heating and drying.

- Width Adjustment screws below support beam prevent contamination of web.

- Width adjustment mechanism easily accessed for maintenance