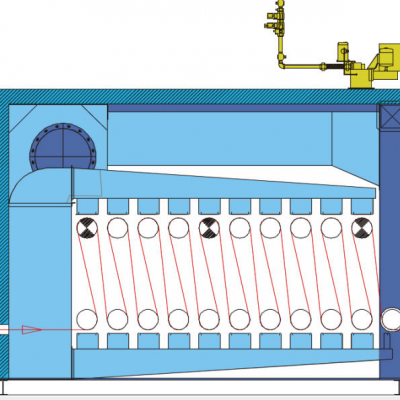

The precise airflow and temperature control of the Matrix Hot Flue ensures all applications perform as required. The highly efficient insulated panels and precise exhaust control minimize energy usage.

The Matrix Hot Flue both increases dye yield and enhances color development, and simultaneously minimizes off-shade problems. Fabric is laced vertically over thick walled rolls and sized to each specific application.

Cooling Zone

Available in a wide range of widths to accommodate different processes, the Navis PlanaTex Cooling Zone is a modular unit that uses plant air to cool the fabric or web after the stenter.

Applications

- Drying after dye application – may be combined with Matrix Metal IR Pre-Dryer

- Pre-Dryer for thermosoling and condensing

- Pad – dry process for thermosoling

- Pad – batch

- Curing Oven after stenter applications

Additional Features

- Advanced nozzle and duct design provide excellent temperature and airflow uniformity

- Precise roll alignment eliminates fabric creases

- Variable speed circulation fans provide drying flexibility

- Full-height access doors for ease of maintenance

- Multiple capacities available to optimize processes

- Compatible with the Navis Compass Control System to manage dwell time and reduce energy consumption