Navis TubeTex introduces the CQC System. The CQC System represents Navis TubeTex’s demand to provide solutions to reduce expenses while improving quality and profits for the fabric and garment producer.

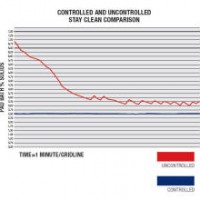

The CQC System actively measures and controls chemical concentration with a precision that was never possible before.

Quality and Savings Benefits:

- Consistent chemical application on the fabric

- Less loose lint in the process, pad, dryer and compaction<

- Less chemical loss during batch changes and bath changes

- Elimination of reworks due to incorrect chemical applications

- Ability to Measure and Control Solids to +/- 0.1% of the Set Point

- Side benefits include increased dryer production

- Reduced Chemical Oxygen Demand due to Chemicals not going to Drain

- Reduced Biological Oxygen Demand due to Chemicals not going to Drain

- Consistent Application of Chemicals from the Start to the End of Each Lot

- Improved Downstream Processing due to Consistent Chemical Application

CQC Layout

The CQC System consists of an Operator Panel, Pump, Mix on Demand (MoD) Sensor, Recycle Tank, and In-Line Filter System, and 3 Chemical Input Valves. The CQC system pumps the solution through the pad’s solution pan, In-Line Filter, MoD Sensor and back to the Pad’s solution system.

CQC System (Standard Installation)

(1) CQC (Constant Quality Concentration) System with Operator Control Panel

(3) Chemical Feeds

(1) Water Feed

(1) Circulation Pump

(1) Recycle Tank Provision (optional)

- Full Recipe Control for all Functionality

- Supervisor Set Tolerances and Alarming

- Setup for Data Collection by Customer System