Stenter Chain & Rail Systems

Stenter Technologies

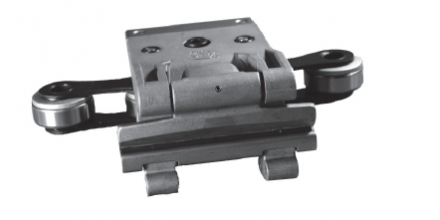

- The Series 2000 is the leading M&W chain system. It incorporates over 90 years of tenter chain experience with the latest metal, plastic, manufacturing and lubrication technologies. Features of the design:

Speeds up to 200 m/m; Loads 25N/mm+

Only requires periodic Relubrication (~8000 hour intervals). Lubrication performed on machine (<8hrs)

High temperature engineered plastic chain bushings for longer life than competitive designs.

Available in Clip, Pin or Combination versions

Clip top knife & plate matched using a proprietary process.

Operates with Low Maintenance Series 2000 Rails

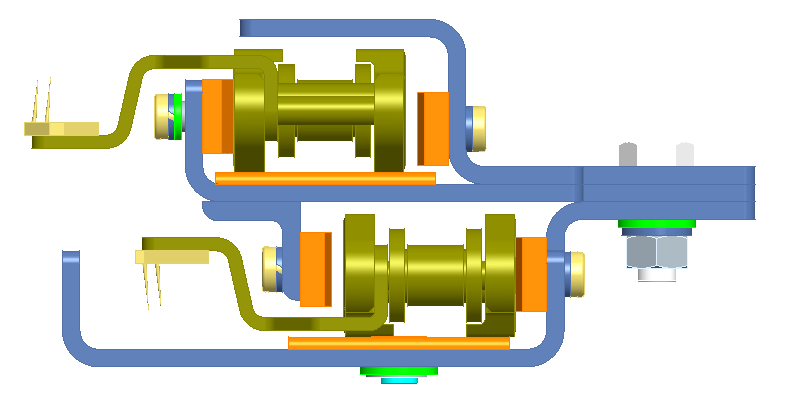

Series 2000 Rail Section

The 2000 rail system is the industries most robust rail system. It is designed for millions of meters /

years of trouble free / low maintenance operations. Details of the system:

- Web pull supported by ball bearing rolling on a spring steel surface. Rolling action uses less

- Power & reduces wear. Spring steel surface designed for life of rails. Flexible Spring steel hinges at each joint ensure smooth rail to rail transition.

- Rail constructed from laser cut plate and extruded shapes. This techniques ensures dimensional stability through years of thermal cycles. This stability prevents pre-mature chain and rail wear.

- Weight of chain supported by carbon, lubrication free, wear strips.

Chain Lube Port patented design allows for grease to be added directly to bearing.

[/vc_column_text][/vc_column]

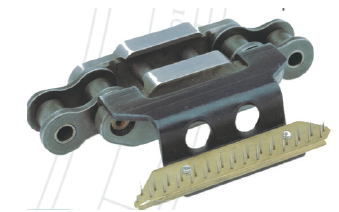

P5 Vertical Pin Chain & Rails

The P5 pin chain is the answer to applications requiring vertical pinning systems. Web control is maintained at even the highest overfeed rates because of the vertical design.

The chain is manufactured using a unique power metal technology. Using powder metal gives an extremely straight pin line, precision lubrication passages and a high strength chain.

- Speeds up to 100 m/m

- Requires minimal lubrication

- Low Profile design for minimum nozzle to fabric distance.

- No replaceable wear pads.

- Rail system protects chain and pins on the return path.

- Formed sheet steel rails prevent oil leakage to floor or surroundings.

- Hard Aluminum Bronze wear surfaces are designed for the life of the rails.

Overfeed Pinning Systems

Proper pinning is the key to successful overfeed and yield control. Available options:

- Belt type or nip type pin-on system

- Pneumatically actuated pinning roll for easy set-up.

- Driven and fixed style center cloth supports

- Steaming systems

- Adjustable tangency scroll rolls

- Skew/Tilt roll

- Individually adjustable draw rolls.

- Plate type or Finger type selvedge uncurlers